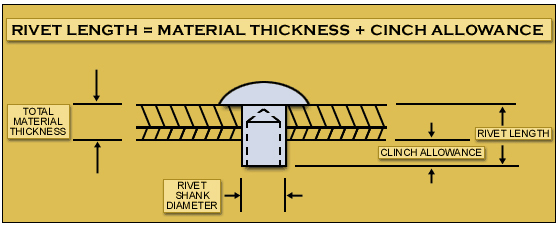

1. What is a clinch allowance?

The clinch allowance is the amount of material required to roll over to obtain a tight fit when riveting.

2. How do I determine the proper length for a rivet?

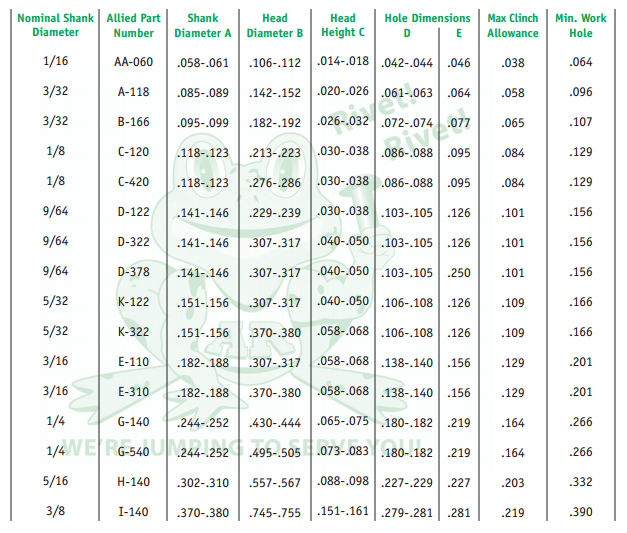

It is actually really simple! All you need is the thickness for the materials you are riveting, plus the clinch allowance for the diameter rivet you require from our chart. Add these two together for the proper length for the rivet you require.

3. What types of rivets do you make?

We make semi-tubular, solid, shoulder and self-piercing rivets, as well as custom-designed product. Call to see if we can make yours!

4. Where does Allied Rivet manufacture their parts?

All of our manufacturing is done at our state of the art facility in Geneva, Illinois.

5. Does Allied Rivet sell rivet machines and related equipment?

No, we do not sell rivet machines and equipment. We do have a list of approved sources that can assist you in any of your equipment needs, so please give us a call and we will set you up with a contact and a phone number.

6. What parts does Allied Rivet keep in stock?

We keep millions of rivets on hand for immediate delivery. For example, the D-378(binder rivet) in lengths of 4/16” through 10/16” in black and white heads, nickel plate and black oxide are kept on hand. Also, our 1/8×2/16 and 1/8×5/32, as well as self-piercing rivets for the ventilation industry are also in stock.

7. What materials does Allied Rivet manufacture with?

We make parts in 1006,1022 and 1038 steel, 302, 410 and 430 stainless steel, and various types of aluminum, brass and copper. Have a special need? Call us to see if we can help.

8. When I call customer service, will I get a recording or will I be able to speak with a live, knowledgeable representative?

At Allied Rivet we strive to always maintain that personal touch. In every case, you will be able to promptly speak with a friendly knowledgeable service representative.

9. What is the smallest body diameter you can manufacture?

.058/.061 body diameter.

10. What is the largest body diameter you can manufacture?

.370/.380 body diameter.

11. Can you color match using a swatch or a PMS number?

We sure can. We use one of the finest painters in the industry with a 30-year proven track record with our company.

12. Is Allied Rivet ISO certified?

Allied Rivet’s quality system is based on ISO 9002:1994. We can provide you with most requested documentation certifying quality, origin, etc. We have over 40 years of experience in providing top quality parts that you can rely on.